District heating Weiz

Client: GRÜBL Automatisierungstechnik Location: Weiz

CONTACT GRÜBL

Markus Zettel

Software and Application

The district heating system in Weiz has increased its resilience against failure and built up reserves to cover peak loads by operating Austria’s first bio-oil boiler that uses cleaned waste cooking oil.

The district heating in Weiz is a wonderful example for the successful combination of sustainability, efficiency, and modern technology in the field of energy supply. The new construction of the boiler house has set new standards with its integration of an advanced biomass and bio-oil boiler. The project was executed by GRÜBL Automation Technology and combined existing plant with modern technologies to ensure an efficient and environmentally friendly heat energy supply. GRÜBL has been an evon partner since the beginning. Today, the company and its more than 100 employees implements a wide range of projects as a system integrator in the field of automation and electrical systems.

New Boiler House

Fernwärme Weiz built the new boiler house in 2019. It contains a new 8 MW biomass boiler and a bio-oil boiler that uses cleaned waste cooking oil in a first for Austria. The 10 MW bio-oil boiler covers the peak loads and ensures reliability. The peak consumption is 650 litres per hour and the 42,000-litre oil tank is organised in six separate individual tanks to prevent mixing and to help control extraction and filling.

Complete Integration and New Technology

The existing plant consists of two biomass boilers providing 5 MW and 6 MW. Thanks to the complete integration of the existing plant into the new control system, the seamless merging and hence efficient control of the two plant areas could be achieved with different operating temperatures and pressures. The entire plant is characterised by high efficiency and is supported by a multi/level heat exchanger and a downstream Economizer that delivers an additional 800-900 kW of heat energy.

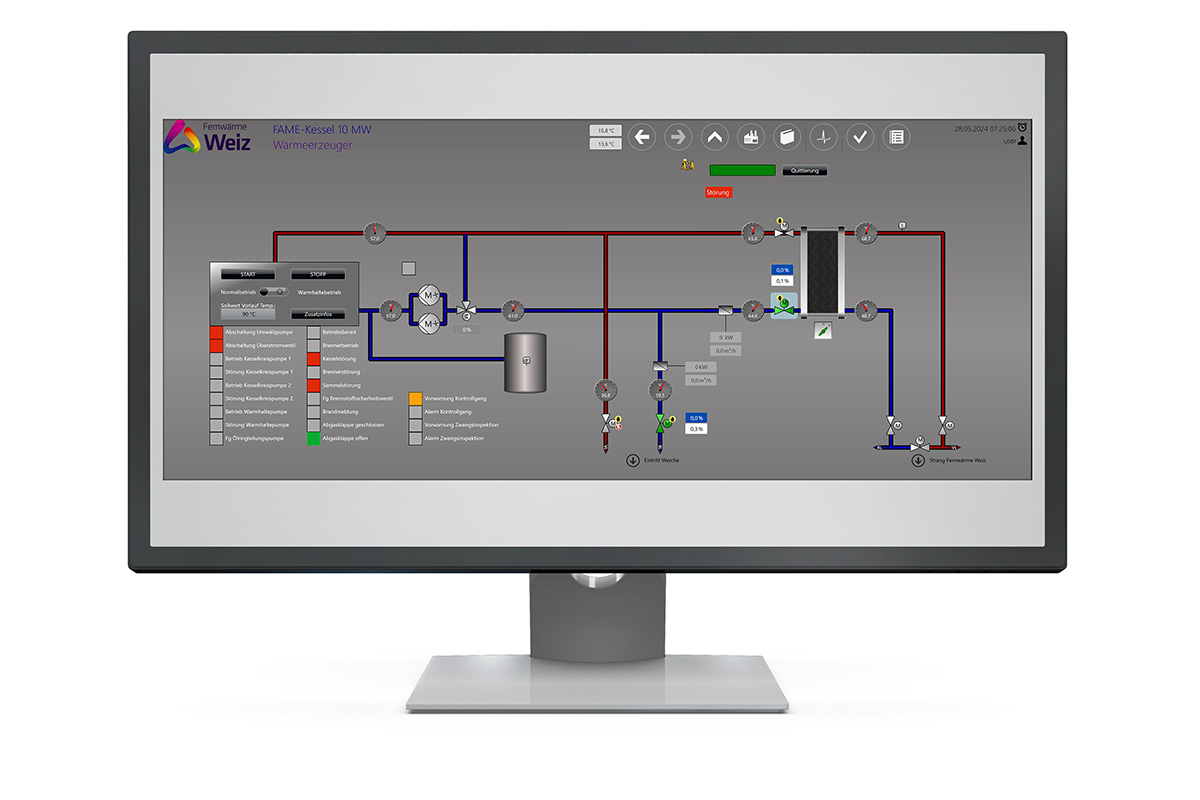

The newly developed control system is based on XAMControl and enables the entire plant to be visualised and monitored. It controls the internal plant hydraulics and controls the entire heat network. This technology ensures optimal network control and guarantees a stable and efficient heat supply for all consumers.

Structure and Consumers

The district heating network in Weiz supplies 890 consumers including households, apartment blocks, businesses, and public buildings. With its 55 kilometres of network and a sales volume of 55 GWh, the network is able to guarantee an aliquot output of 44 MW with a simultaneity factor of 0.6. The network calculation and simulation are done via differential pressure measurements at the transfer stations.

The district heating network in Weiz contains over 600 physical data points that are managed via a central server and redundant sub-controllers. The hardware components enable manual intervention and 12 pumps with a total power of 480 kW ensure the reliable distribution of the heat energy.

Environmental Benefit and CO2 Savings

One outstanding feature of the district heating in Weiz is the significant reduction in CO2 emissions. Compared to individual heating systems, this district heating system produces considerably lower emissions. The annual saving is an impressive 10 million kilograms CO2. In addition, the Energy Holding can deliver up to 11 MW of extra energy on request, which further increases the flexibility and security of supply.

Summary

The district heating company Fernwärme Weiz has shown how the combination of innovative technologies and sustainable energy concepts can be used to implement an efficient and environmentally friendly heat energy supply. The newly built boiler house and the integration of modern boiler technology has allowed Weiz to set new standards in regional energy supply and to make a major contribution to the reduction of CO2 emissions. Austria’s first bio-oil boiler that operates using cleaned waste cooking oil increases the reliability of the district heating in Weiz and builds up reserves to cover peak loads.

Kontakt

More about the evon Projects in Building Management?

Fill in the form below our call Lukas Riegerbauer!