Wojnar's

Client: ELIN GmbH Location: Wien

ELIN Vienna is replacing the partially 40-year-old technology during live operation, without interrupting production, by using evon XAMControl.

Wojnar's Feinkost

Wojnar's is an Austrian company specialising in the production and sales of gourmet food. Founded in 1932, the family business is based in Vienna and is well known for its delicious salads, pâtés, and fish products. Wojnar's place great emphasis on quality and mainly use regional ingredients. The company is part of the Vivatis Group. ELIN’s subsidiary in Vienna converted the control technology in this project to evon XAMControl and in doing so made the first step towards a 360-degree management platform governing the areas of buildings, energy, and production.

ELIN: Pioneer in Electrical Technology and Automation

ELIN is the market leader in Austria for building automation and electrical plant. As a leading Austrian company with 130 years of history, ELIN has a mature and comprehensive set of expertise, many years of experience, and renowned competence in specialised areas. ELIN designs, builds, maintains, and services buildings and industrial and infrastructural facilities in its electrical technology portfolio.

evon XAMControl and Vivatis

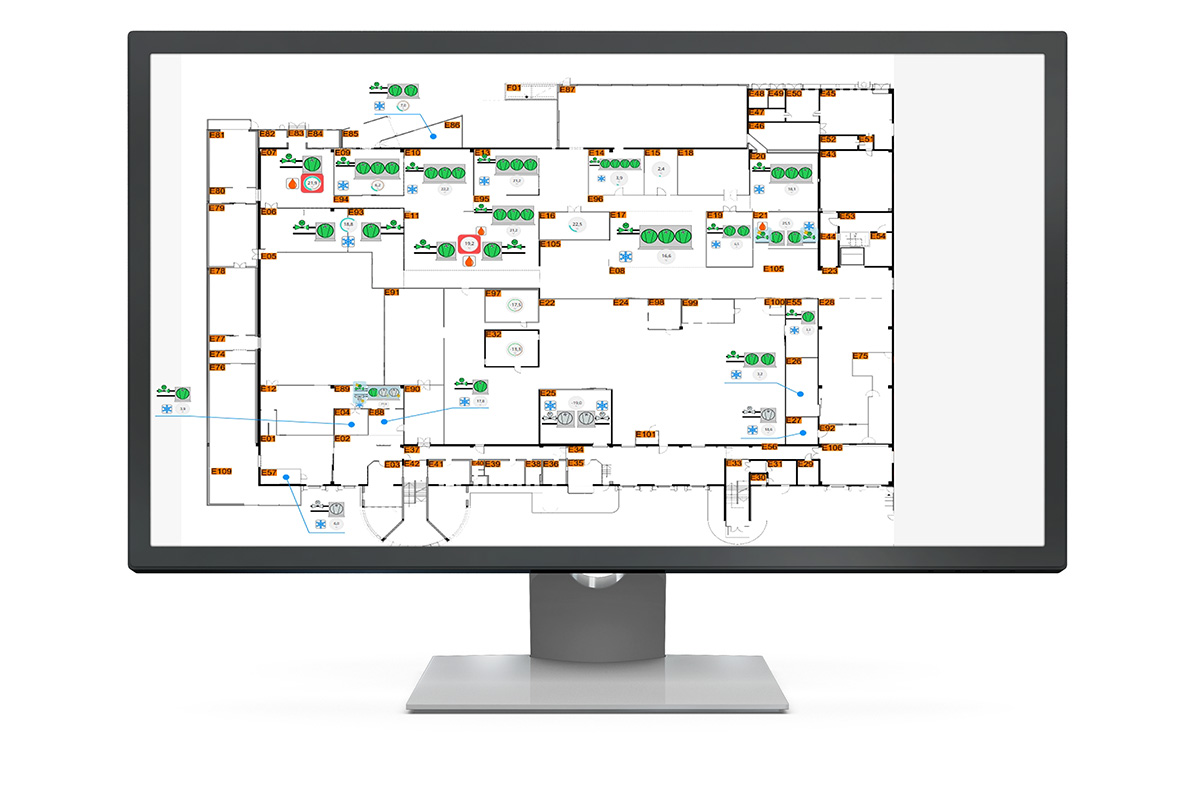

evon is already well-known within the Vivatis Group. The project at Wojnar's means that another company with the group will be modernised with the help of evon XAMControl, which underlines the trust being placed in the system and the outstanding partnership. The new management technology assumes the measurement and control activities for heating, ventilation, climate control, and chilling rooms in the production plant.

The roadmap for the modernisation is ambitious: the decision to start fell at the end of 2023 with the goal of finalising the first phase of the project by September 2024.

Technical Features

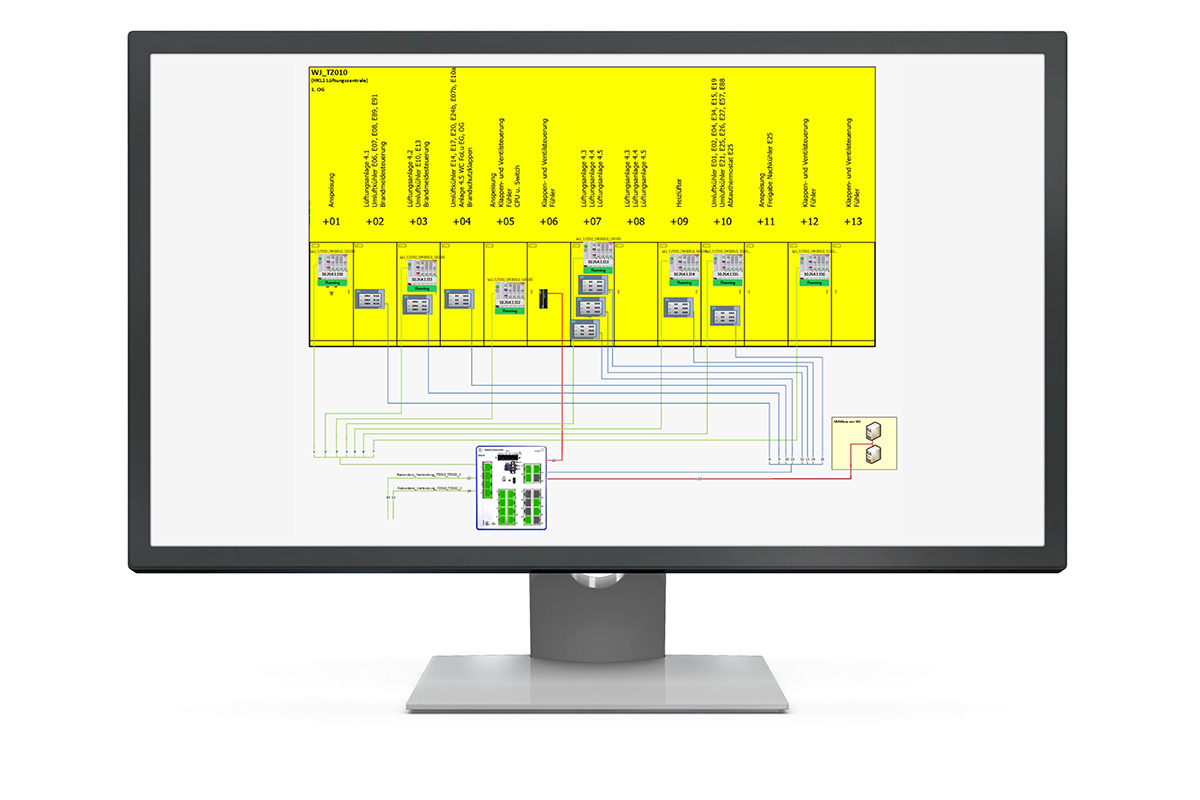

The modernisation consists of around 4000 data points managed by a virtual server and two redundant controllers. Twenty new switching cabinets were required to house 18 Beckhoff bus couplers with the associated IO boards, a redundant network system, two 22” HMIs, and 14 power meters. This infrastructure ensures high uptime and flexibility of operation.

Refurbishment without interrupting production

One of the greatest challenges was to carry out the rebuild during live operation without violating the strict temperature set points, particularly in the chilled warehouses where the temperature needed to be kept constant, in some cases down to -18 degrees Celsius (+/- 2 degrees). The integration of the new software with the 40-year-old periphery including valves, motors, and sensors, required a new flexible style.

Goal: 360-degree management technology for the entire site

The overarching goal of the modernisation is to provide Wojnar’s with a complete 360-degree digitalisation solution of the building management system, over all energy consumers, down to production. Over the course of the project, 4 different existing management technologies for different trades were to be integrated. The new energy measurements were not just intended for monitoring but also to be used as a tool to help the operation of individual aggregates.

This comprehensive modernisation ensures that Wojnar's can shape its production processes to be efficient and sustainable in the long term. The implementation of modern management technology and energy management systems makes a significant contribution to Wojnar's competitiveness and sustainability.

Contact

More about the evon Projects in Building Management?

Fill in the form below our call Lukas Riegerbauer!