Enhancing Downstream Processing

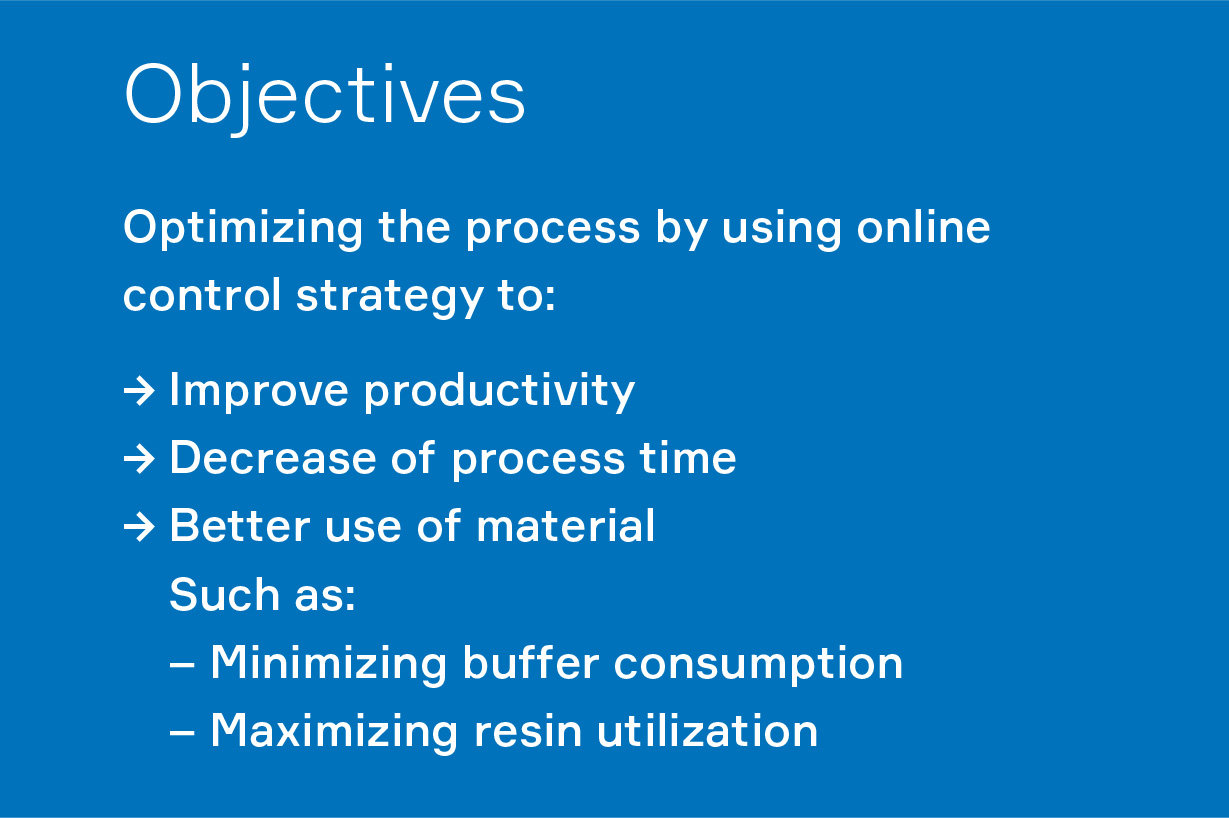

in Biopharma up to 50%

Streamlining Downstream Processing

Downstream processing plays a critical role in biopharmaceutical manufacturing. It involves purifying therapeutic proteins and isolating and stabilizing them from other cellular components produced at upstream processing. Through a series of unit operations, including filtration, chromatography, and separation techniques, we achieve the highest levels of purity and potency for the desired protein product. With our innovative online controller algorithm, we have been able to streamline this process, significantly reducing processing time and enhancing sustainability by minimizing buffer consumption.

Driving Sustainability in Biopharmaceutical Production

Downstream processing plays a critical role in biopharmaceutical manufacturing. It involves purifying therapeutic proteins, isolating and stabilizing them from other cellular components produced at upstream processing. Through a series of unit operations, including filtration, chromatography, and separation techniques, we achieve the highest levels of purity and potency for the desired protein product.

Optimizing Performance for Superior Results

Our implementation of MPC-EKF in cation exchange and affinity chromatography has yielded remarkable improvements in process performance. By reducing processing time for a specific resin utilization level, we have achieved productivity levels beyond what is feasible with traditional chromatography methods. As a result, buffer consumption has been reduced by up to 43%, leading to a significant decrease in the cost of goods (COG) and minimizing the environmental impact of the chromatography process.

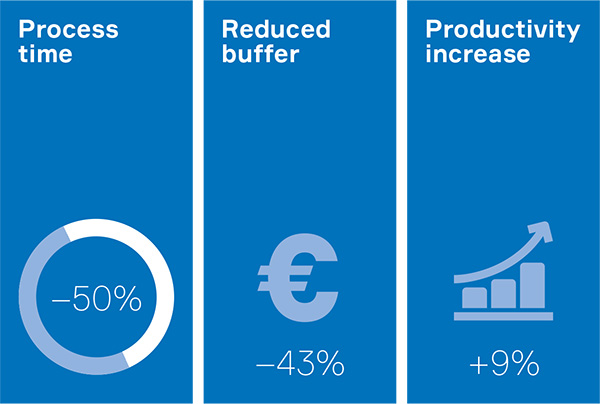

Enhancing Control with Model Predictive Control (MPC)

Through our innovative experiments, we have combined Model Predictive Control (MPC) and Extended Kalman Filter (EKF) techniques to optimize the efficiency of the chromatography step. Our aim is to continuously monitor the system and adjust loading volume, accounting for uncertainties such as resin degradation or model discrepancies. By leveraging MPC, we can reduce processing time by nearly half while optimizing resin utilization and minimizing buffer consumption.

Efficiency without Complicated Hardware

Our approach offers an efficient solution without the need for complex hardware, unlike multi-column continuous counter-current loading strategies. This simplicity of implementation allows for consistent operation over time, even when dealing with varying feed concentrations.

Conference Paper - Download

Soft sensors to control aging of chromatography columns, summarised in one PDF.

Online optimization of dynamic binding capacity and productivity by model predictive control

Discover our groundbreaking algorithm for precise loading control via residence time adjustment, and an online optimization technique that conquers noisy data and enhances model accuracy. Achieve exceptional productivity, resin utilization, and low buffer consumption, all with superior simplicity to counter-current chromatography. Learn more here.

Residence time gradients during loading increase dynamic binding capacity and productivity

Explore our featured scientific work offering an algorithmic solution for boosting productivity and dynamic binding capacity in protein chromatography. Learn about our validated controller that optimizes flow rate gradients during loading, resulting in a remarkable 68% increase in productivity for Protein A chromatography, all detailed through the link.

Contact

More about the Potential of Downstream Processing in Biopharma?

Make an appointment now or call our specialist Dr. Touraj Eslami!