evon XAMControl SCADA, Data Acquisition

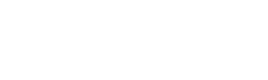

evon XAMControl combines modern software technology with an open system design. Thanks to its scalability, evon XAMControl is used in different applications over a wide range of sectors. As a SCADA or process control system, evon XAMControl ensures the overview, transparency and control of production, processes and resources.

In the spirit of Industry 4.0, evon XAMControl is the basis for networking and data acquisition in the area of standard and special machine construction.

If the task is to network several machines and systems in a production line, then they can be integrated into evon XAMControl via the standard interfaces. The thus centrally acquired data then form the basis of reporting and evaluation for optimization, the reduction of costs, and the conservation of resources.

Areas of application: HMI/machine visualization, SCADA & process control systems, line management, Operational and Machine Data Acquisition

Sectors: Machine and plant construction, metal processing, automotive, environment and recycling, foodstuff and drink, chemical and plastic

Modern Visualization

Classical systems offer the possibility of visualization and enable machines and plant equipment to be controlled via a graphical user interface. However, current further developments are changing customer requirements. An innovative and secure platform such as evon XAMControl offers more today than your customers are used to and is continually being updated to match these requirements:

- Intuitive visualization and operation

- Simple data recording in a database

- Automated alarms and fault notifications via SMS/email

- Interfaces to many PLCs and control manufacturers

- Comprehensive library for rapid and efficient engineering

- Ready for Industry 4.0 and Internet-of-Things (IoT)

Line management with evon XAMControl

A production line combines a number of very different machines, plant and devices. The line management provided by evon XAMControl not only provides you with an overview, but also enables you to react quickly to changes und unforeseen circumstances. It supports you with clear analyses and recommendations for step-by-step optimization.

During live operation, your production team is supported and kept up-to-date with real-time information about the status of the current batch, alarm situation and events. Thanks to integrated reports and statistics, this data is available for all forms of analysis and help you to optimize production.

Process control engineering

on XAMControl basis

Download now!

evon XAMControl in the field of process control engineering summarized in a PDF.

Manage energy and resources

evon XAMControl fulfils all requirements placed on an energy management system (EMS) according to the DIN standard EN ISO 50001. The core task of an EMS is to provide basic data for the deliberate control and continuous optimization of energy consumption.

evon XAMControl offers all technical possibilities to acquire, archive and evaluate energy and counter data from a wide range of media. Based on this data, timely decisions can be made and process flows can be adapted to avoid energy peaks being exceeded and this saving energy and money.

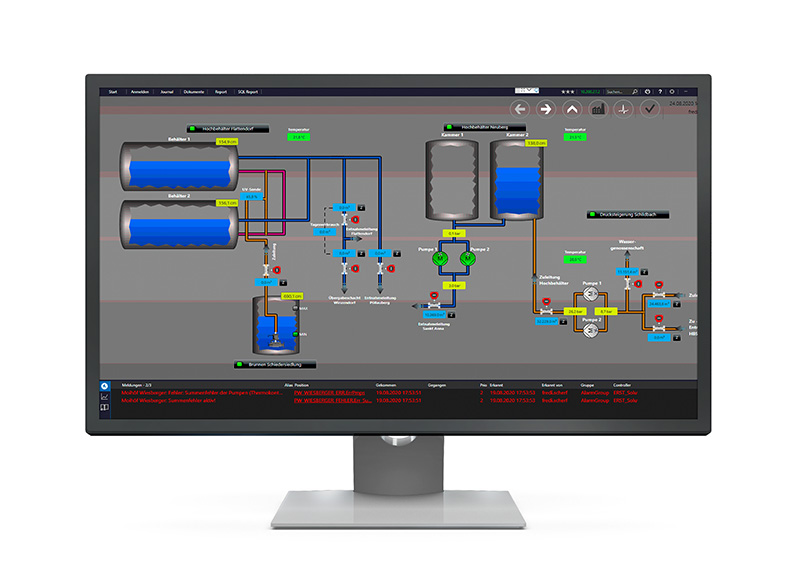

Increased Efficiency Thanks to OEE

The productivity and effectiveness of your machines and plant equipment can be monitored using the OEE evaluation in evon XAMControl (Overall Equipment Effectiveness, OEE). OEE is a KPI in the context of production processes that helps measure, monitor and improve the overall effectiveness of your production plant (machines, manufacturing cells, conveyor belts, etc.).

OEE takes the most frequent and important sources of productivity losses in manufacturing into account. The OEE value consists of three factors: Availability, performance and quality.

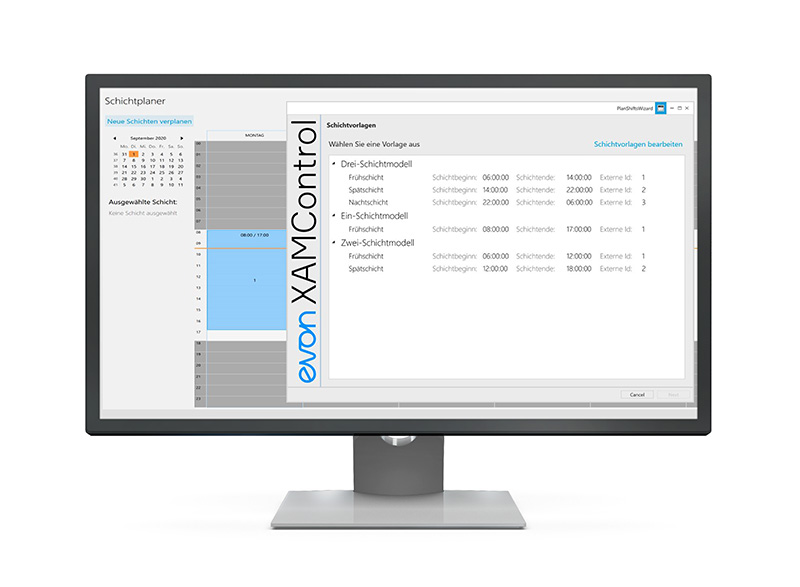

Improved Planning

Use the new shift planner in evon XAMControl to plan the production times and the shift model. A range of different shift models can be saved and used for planning. It is also possible to change the working times for individual days thus reacting flexibly to production requirements.

All times are stored in a separate database and archived historically. They are then available at a later date for evaluation. The shift planner also enables you to plan future production activities and provides you with an overview of your previous shift times.

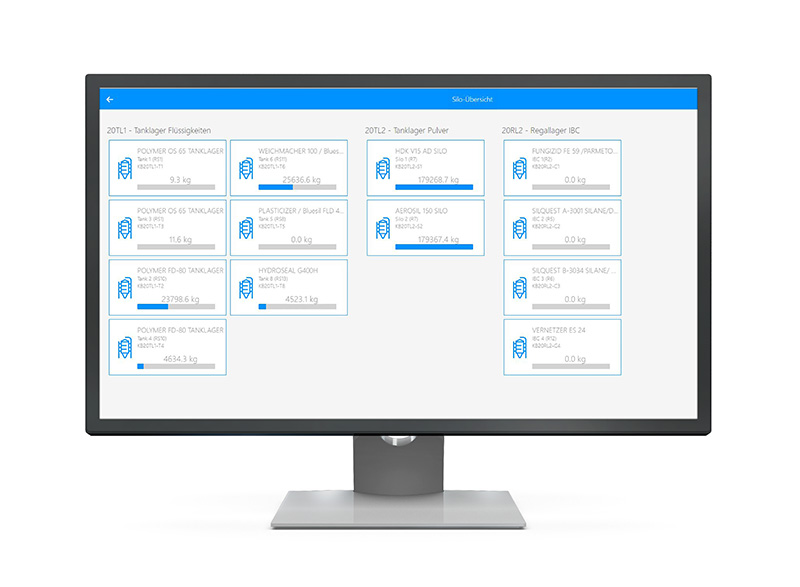

Web Visualization

The Web visualization (HTML5) enables you to access current production KPIs or stock levels from any device. evon XAMControl handles the authentication process to ensure that only authorized personnel are given access to current production data. Our HTML5 visualization provides an overview of current stock levels, planned production jobs and current machine stati.

Success Stories

Projects in the area of industry

Contact

More about the evon Projects in SCADA, Data Acquisition?

Fill in the form below!